I hope it doesn't come as a surprise that all 3D printing is bad. It's bad for you, and it's bad for the environment. Traditional FDM techniques aren't great, but the SLA/DLP resin processes that this article focuses on present an even greater risk. If you're only interested in the highlights, here's the long and short of it:

- Resin printing contains inherent hazards, but they are manageable. Similar to using spray paints, one can easily mitigate nearly all risk by taking proper precautions such as proper ventilation and personal protective equipment.

- The entire lifecycle of resin printing is hazardous. That means before printing, while printing, during post-processing, and even fully cured models.

- The biggest dangers are high exposures to carcinogens, and the development of severe, life-long allergies. Lesser dangers include skin and respiratory irritation, as well as general inflammation. This is inherent to resin, but using plant-based or low-odor resins may help reduce risk.

- The hazardous fumes are often colorless and odorless. But if you can see resin or smell fumes, you are in danger. Anytime you're around uncured resin, you should be wearing nitrile gloves, safety glasses and a respirator. I don't mean N95 masks, but true and proper NIOSH P100-rated respirators.

- An ideal resin printing workshop should emphasize preventing leaking fumes into human-occupied spaces, and a high rate of air exchange. HEPA and activated carbon filters have been shown to also help reduce harm.

- Your workflow should prioritize getting uncured resin and cleaning solutions out of the equation as quickly as possible. That means filling and emptying the vat, and storing cleaning solution, as soon as they're no longer in use.

My Background

Despite the risks, printing and painting models is one of my favorite hobbies. Resin printers open up a whole new world of access to models. They're also functionally useful in many ways, from printing simple items like guitar picks to replacing obscure parts around the house. All that to say, I'm a hobbyist. I don't have a background in chemistry or material safety. I'm not qualified to give professional medical or safety advice, so I encourage you to read the sources listed at the end.

I first got into the 3D printing hobby space years ago, and at the time research was fairly sparse on the topic. I did my due diligence at the time, but it involved a lot of cobbling together material data safety sheets (MSDS) and trying to infer and apply information from vaguely relevant studies. It didn't help that there wasn't much transparency in the industry, which unfortunately continues to this day. Manufacturers are often from countries with low consumer safety protections. They will frequently market their resins towards the safety crowd, labeling resins as plant-based, water-washable or low odor. These vague terms imply that they're better for you (or the environment) in some way, but the statements are rarely backed with any sort of objective definitions or data.

My conclusion at that time (circa 2019) was that resin printing wasn't great, but also not wildly dangerous. I reasoned that there were plenty of other household chemicals like bleach which were equally hazardous. I wore gloves and a mask, and isolated active printing from my living spaces. As I've since learned, this was an understatement and I should've taken more serious precautions.

I recently decided to upgrade my first-generation Anycubic Photon to one of the current generations of printers (Saturn 4 Ultra 16k). I've also moved since my last project, and no longer have a garage for my printing setup. This forced me to start digging back into the research, and I found that there's much more research available into these printers and their hazards. Without further ado, let's dive into things and pick apart just how bad they are!

The Chemical Perspective

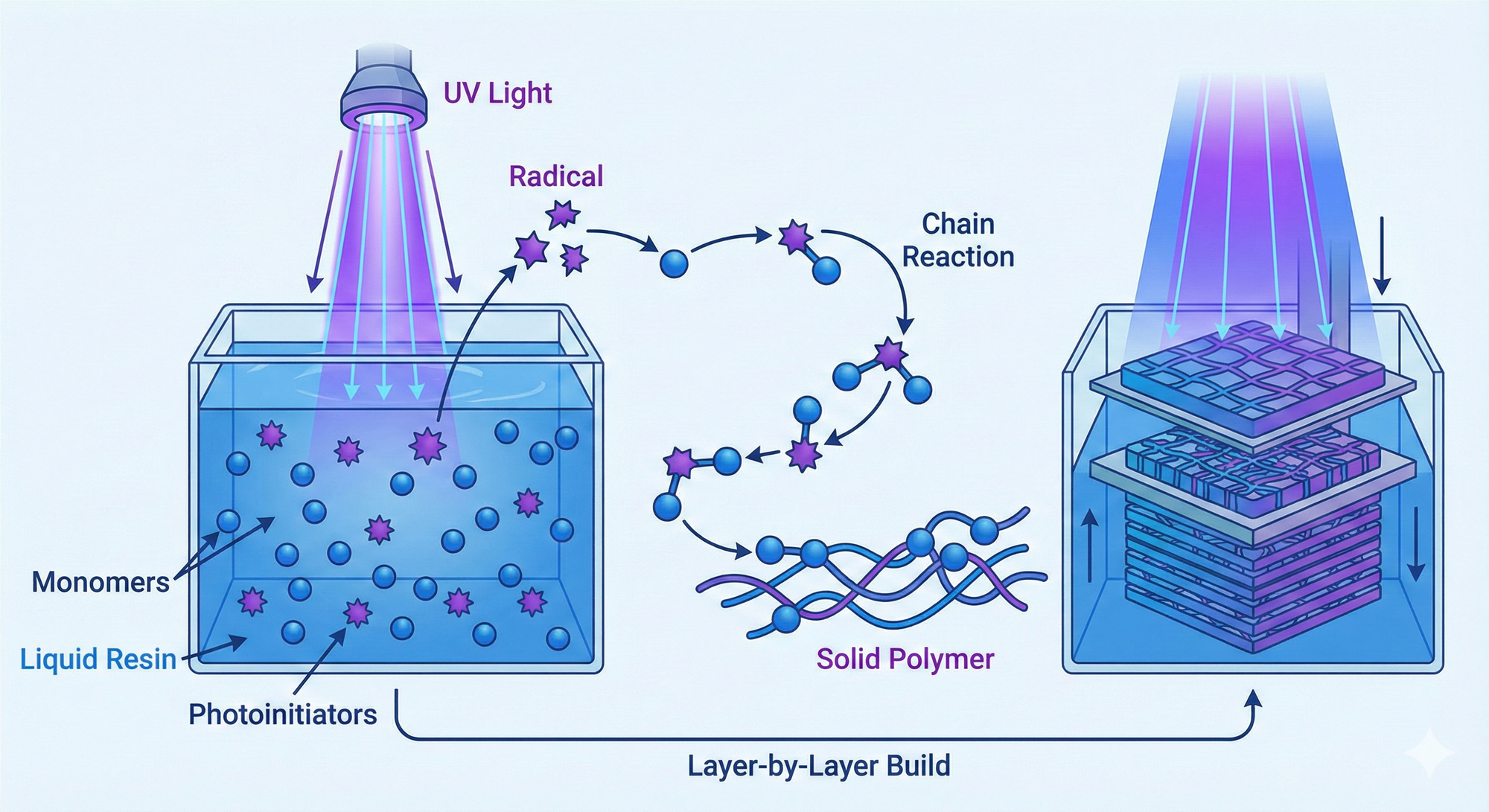

At the heart of resin-based 3D printing is photopolymerization1, which is the process of taking a liquid (resin) and using UV light to permanently change it into a solid. The basis of polymerization chemistry is the humble monomer, which is a small molecule that has the potential to bond with other monomers, thus forming a polymer. An example of a naturally occurring monomer is the simple sugar glucose, which chains together to form carbohydrates.

In resin printing, a stable solution of monomers and photoinitiators is constructed. At its resting state, these two key components are just floating around in solution. With the addition of UV light, we can trigger the photoinitiator. It takes the energy from that light and creates a free radical. If you're unfamiliar, these are essentially highly-reactive molecules. The free radical then goes on to initiate the chemical process of double-bonding with the monomers. And thus the polymerization chain reaction is kicked off. The radical double-bonds with a monomer, triggering another radical, which double-bonds with another monomer, and the cycle continues. The final result is huge chains of the newly-formed polymer, which are now stable.

Many of the hazards from 3D resin printing come from the fundamental necessity of monomers in the process. While monomers are a broad classification, being small and naturally reactive generally wreaks havoc on our biology. They have the ability to wiggle their way through the skin barrier, and into the tiniest little crevices of our lungs. They are irritating, but also fundamentally damaging to both chromosomes and DNA2.

Aside from direct damage to DNA and its structures, many of the chemicals in resin are known carcinogens (e.g. formaldehyde, ethanol) and known sensitizers (e.g. methacrylates)3. For those who may not know, sensitizers are compounds which induce an immune response. While negligible on first contact, the immune response gradually gets worse with exposure. It will eventually evolve into increasingly severe responses. So while you may feel no harmful effects to resin exposure at first, over time you could develop rather severe allergies. This is not a reversible or treatable condition, and would be a life-long problem.

The Primary Hazards

We know that uncured resin is a concoction of many nasty chemicals which pose risks just by existing. One example is antimony, a toxic heavy metal used commonly as the photoinitiator in resins. Many resins contain up to 10% antimony by weight, and an estimated 3% of that is leeched into the environment4. Antimony is generally regarded as harmful5, irritating our skin and eyes on contact. But not touching something is relatively easy, when compared to not breathing something. And that's where the biggest concern from resin comes into play. Not through direct contact, but indirectly through the gases which resin constantly emits.

Many hobbyists have the misconception that harmful gases are only present during the printing process itself. Unfortunately, that's not the case! This is because many of the chemicals in resin are constantly evaporating, even at rest. These gases are collectively known as volatile organic compounds (VOCs), and one study found that the emission of these particles remained relatively similar throughout the print, wash and cure phase. In fact, they even discovered that the total VOC concentration continued to increase after the print was finished6.

These are not negligible amounts of emissions. The same previously referenced study found that someone near a printer could be exposed to dangerously high amounts of VOCs, for example six times the reference exposure level of formaldehyde. It's interesting to note that two studies7,9 have shown that plant-based and low-odor resins do generally release fewer harmful VOCs. Regardless, the clear conclusion is that resin should be bottled up as quickly as possible.

One saving grace regarding VOC emissions is that air exchange rate plays a crucial role in reducing risk. As an extreme example, one study6 found that if the size of the printing area was increased to ~30m3 and the air exchange rate was roughly that of the outdoors, exposure levels for all of the chemicals of concern fell below the harmful ranges reported in regulations and guidance documents. This is both alarming and relieving: firstly, the amount of space and air exchange required to achieve this drop in exposure is very large. However, it's relieving to know that these levers exist, and therefore one can minimize their risk by increasing these parameters as much as feasible.

Secondary Hazards

Aside from VOCs, two sources of under reported risk are the cleaning and waste management processes. Cleaning solutions, typically Isopropyl alcohol (IPA), are irritating in and of themselves. However, by nature of being able to clean the uncured resin, they also increase the bioavailability of the harmful chemicals8. They also give a false sense of safety to the user, who might be less careful when handling spills or waste from the post-cleaning solutions and processes. For both self and the environment, it's best to minimize exposure during cleaning, and to carefully collect all your used cleanup supplies. I would recommend investing in some clear garbage bags, which you can then set into sun for a while to help cure the remaining resin before transporting it to your general waste.

It may also be surprising for many hobbyists to learn that even cured prints are not entirely safe. One study from the Journal of Toxicology and Environmental Health10 has noted that the manufacturer's recommendations for curing is often insufficient. They also cited a few studies, and reproduced the results themselves, to find that properly cured prints continue to emit harmful VOCs!

While the risk from inhalation in cured prints is relatively low, prolonged skin contact will still result in all of the same nasty side effects previously discussed: cytotoxins, irritation and sensitization. It's important to note that the context of this study was specifically dental uses, and that the exposure for most hobbyists is comparatively minimal. For those who are especially risk-adverse, or using their resin prints for things like jewellery or children's toys, it would be wise to keep this in mind. The final recommendation was to let cured resin prints sit for four weeks, after which time the harmful emission rate had been reduced by 90%.

Conclusion

Resin-based 3D printing has gained popularity in recent times, and there has been an influx of credible studies assessing the hazards. Information is the crucial first step towards consumer protection and understanding, and I'm pleased that we now have this type of data handy. It's also wonderful that the general community consensus has already been aligned around solid PPE and risk mitigation for years.

Nonetheless, I frequently see people on forums or YouTube neglecting even the most basic safety precautions. Through my research here, I also believe that even the cautious crowd should be taking some notes about how to better protect themselves. There's a lot of good information that propagates through the community, but also tons of misguided and even downright incorrect information.

Much of the gaps come from ignorance, as I was before starting this article. My hope is that this can be a resource to learn from primary sources, rather than relying on common consensus and the hobby zeitgeist.

Be safe, and happy printing!

Sources

All of these citations are useful, but if I were to recommend a single one for the hobbyist to read, it would be the sixth: "Emissions and Chemical Exposure Potentials from Stereolithography Vat Polymerization 3D Printing and Post-processing Units." This study is comprehensive and covers virtually all of the deep technical questions one might have about resin printing.

- Photopolymerization-based additive manufacturing for the development of 3D porous scaffolds

- Genetic and cellular toxicology of dental resin monomers

- State of the art in additive manufacturing and its possible

chemical and particle hazards—review - 3D Printing (Rapid Prototyping) Photopolymers: An Emerging Source of Antimony to the Environment

- The exposure to and health effects of antimony

- Emissions and Chemical Exposure Potentials from Stereolithography Vat Polymerization 3D Printing and Post-processing Units

- Assessing the Occupational and Environmental Risks of Resin-Based 3D Printing in Dental Clinics: Airborne Chemical Emissions and Mitigation Strategies

- Acute and Chronic Toxicity of Uncured Resin Feedstocks for Vat Photopolymerization 3D Printing to a Cladoceran (Ceriodaphnia Dubia)

- Volatile Organic Chemical Emissions from Standard and “Eco” Resins for Vat Photopolymerization Additive Manufacturing (“3D”) Printers and Potential Mitigation Strategies

- Organic compound and particle emissions of additive manufacturing with photopolymer resins and chemical outgassing